DY News

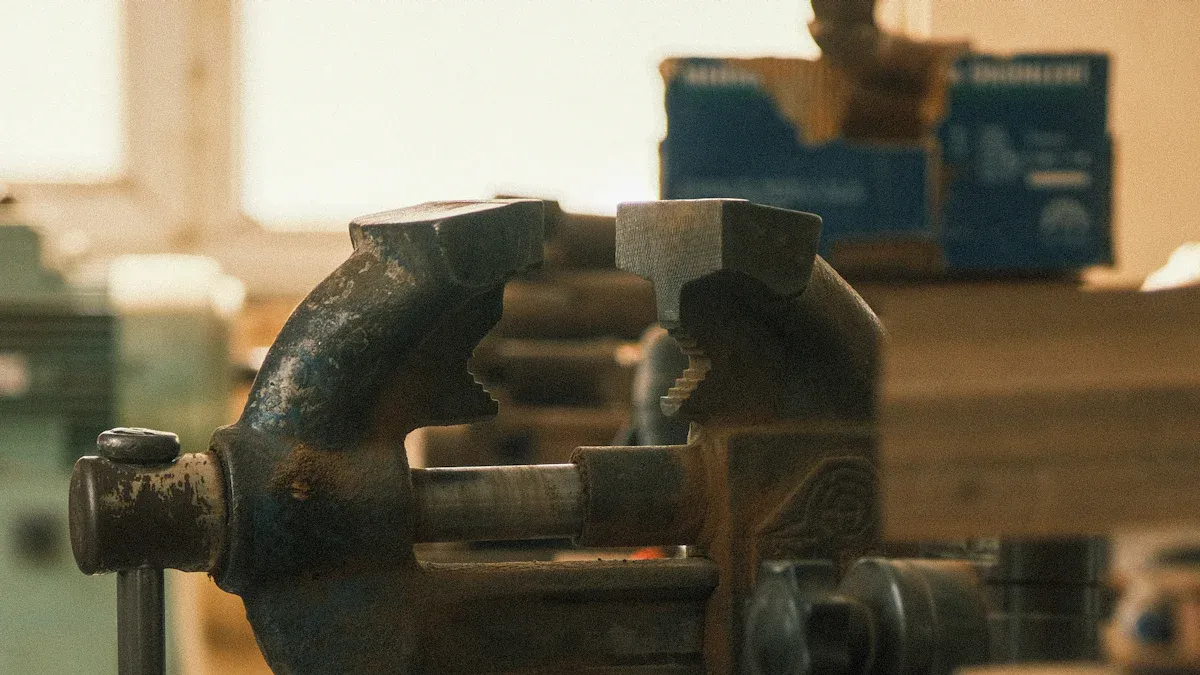

Exploring the Many Kinds of Machine Vises for Your Workshop

Choosing the right machine vise is essential for any workshop. It directly impacts the quality and accuracy of machined parts. A proper vise ensures workpieces remain securely held during operations. This prevents movement that could lead to errors or damage. Furthermore, selecting the correct machine vise significantly enhances safety for the operator. A stable setup minimizes risks of accidents. Therefore, workshops must prioritize careful selection of this critical tool.

Key Takeaways

Choose the right machine vise for better work quality and safety.

Standard vises are good for general tasks and are cost-effective.

Precision vises help with very accurate work and make many parts the same.

Self-centering vises save time by quickly lining up parts.

Power vises use hydraulics or air for strong clamping and less work for people.

Match the vise to your workpiece size, material, and the job you need to do.

Clean and check your vise often to make it last longer and work well.

Essential Machine Vise Types for Every Workshop

Workshops use many different machine vise types. Each type serves specific purposes. Understanding these differences helps operators choose the right tool. This choice ensures precision and efficiency.

Standard Milling Machine Vises

Workshops often use standard milling machine vises. These vises are fundamental for many machining tasks. They securely hold workpieces during milling operations. Machinist vises are traditional vises. They are frequently found on manual milling machines. These vises can be fixed to the machine table. They come in variations with either a swivel or permanent base. This makes them excellent entry-level choices. Metalworking vises are also common. People often call them machinist or engineer vises. They hold metal parts for processes like cutting and filing. They are typically made of cast iron. This provides strength and affordability. They feature removable jaws. These jaws can be coated with soft materials for delicate work. Universal machine vises are highly practical. They are frequently utilized. They work in various directions. This includes horizontal, vertical, and angled positions. This makes them suitable for production tools.

Fixed Base Machine Vises

Fixed base machine vises offer maximum rigidity. They bolt directly to the machine table. This setup provides a stable platform. Operators use them for heavy cuts. They are ideal for repetitive tasks. Their fixed position ensures consistent workpiece placement. This consistency helps maintain accuracy.

Swivel Base Machine Vises

Swivel base machine vises provide greater flexibility. They allow operators to rotate the workpiece. This rotation happens without unclamping it. A graduated base shows the angle. This feature is useful for machining multiple sides. It also helps with angled cuts. Operators can quickly adjust the workpiece's orientation.

Precision Grinding Machine Vises

Precision grinding machine vises are for high-accuracy work. They hold parts with extreme precision. These vises are crucial for grinding operations. They ensure tight tolerances.

Toolmaker's Machine Vises

Toolmaker's machine vises are highly accurate. They feature hardened and ground surfaces. This ensures parallelism and perpendicularity. They hold small, delicate parts. Toolmakers use them for precise grinding. They also use them for inspection tasks. Their design minimizes deflection.

Sine Machine Vises

Sine machine vises allow precise angle setting. They use gauge blocks to set angles. Operators place gauge blocks between rollers. This creates a specific angle. They are essential for grinding precise tapers. They also help with angled surfaces. This method offers very high angular accuracy.

Specialized Machine Vises

Specialized machine vises address unique workholding needs. They offer solutions for complex geometries. They also provide efficiency for specific production demands.

Angle Machine Vises

Angle machine vises position workpieces at an angle. They offer a significant advantage over standard vises. This is true in applications where the workpiece needs an angled position. This includes tasks like drilling, cutting, or reaming. They also help with finishing light-duty milling. This is particularly useful when creating angled holes. Unlike conventional drill press vises, angle vises adjust the clamped workpiece up to 90 degrees. This allows optimal positioning for these angled operations.

Self-Centering Machine Vises

Self-centering machine vises automatically center the workpiece. They ensure the part's center aligns with the machine's spindle. This is vital for consistent machining. They are frequently used in EDM environments. They also appear in pallet or automation systems. Many 3, 4, and 5-axis CNC machines use them. These vises handle light-to-medium machining. This includes materials like aluminum and plastics. They also manage heavy-duty machining. This involves materials like steel, titanium, and Inconel. Operators use them for center drilling, chamfering, and boring. They perform a wide range of machining operations. This includes drilling, tapping, boring, and finishing applications. They are suitable for both conventional and CNC machines. A 5th Axis self-centering vise can exert a clamping force of 25.0 kN. This demonstrates their powerful grip.

Hydraulic and Pneumatic Machine Vises

Hydraulic and pneumatic machine vises use fluid power. They provide high clamping forces. Operators control them with a lever or button. This reduces manual effort. An Orange Vise dual station vise has a maximum recommended clamping force of 7200 lbs. Samchully power vises offer a range of clamping forces. These range from 2,250 to 7,868 lbf. Operators can adjust this force via a one-touch preset dial. These power vises are ideal for high-volume production. They also excel in automated setups. They increase efficiency and reduce operator fatigue.

Understanding Each Machine Vise's Primary Application

Each machine vise type serves specific functions in a workshop. Understanding these applications helps operators select the best tool for the job. This ensures optimal results and efficiency.

General Machining with Standard Machine Vises

Standard machine vises are workhorses for many general machining tasks. They offer versatility for various operations on milling, planing, and drilling machines.

Facing Operations

Facing operations involve removing material from a workpiece's surface to create a flat finish. Operators often use standard milling vises for this task. These vises securely hold the workpiece, allowing the milling cutter to pass across its top surface. This process ensures a smooth and level plane.

Slotting and Keyway Cutting

Standard milling vises also excel at slotting and keyway cutting. Slotting creates grooves or channels in a workpiece. Keyway cutting involves machining a specific slot for a key to prevent relative rotation between parts. CNC machine vises and QH machine vises are widely used for these operations. They provide the necessary stability for precise cuts.

High-Precision Tasks with Grinding Machine Vises

Grinding machine vises are essential for jobs demanding extreme accuracy and fine finishes. They handle tasks where standard vises cannot meet the required tolerances.

Grinding Flat Surfaces

Precision grinding vises are specifically designed for grinding ultra-flat surfaces. They feature hardened stainless steel construction, ensuring extremely high accuracy and parallelism. Operators use these vises on surface grinders to achieve mirror-like finishes and tight dimensional control. Achieving high precision in grinding requires careful attention to several factors. Selecting the correct grinding wheel is crucial, considering material, desired finish, and grinding method. Proper workpiece assembly and support minimize vibrations, ensuring a solid grinding operation. Precise control over grinding specifications like depth of cut, speed, and feed rate is also vital for quality. Additionally, dressing and truing the grinding wheel ensures consistent cutting performance.

EDM Applications

Electrical Discharge Machining (EDM) requires precise workpiece holding. Grinding machine vises, particularly toolmaker's vises, are often used in EDM applications. Their high accuracy and rigid clamping ensure the workpiece remains perfectly still during the electrical discharge process. This precision is critical for creating intricate shapes and fine details. A powerful clamping force, often around 29 KN, secures the workpiece, preventing movement under high pressure. A high-strength screw rod allows smooth, precise rotation and controlled movements for fine adjustments. A smooth surface and precision jaw also enhance accuracy, holding the workpiece in the correct position for high-quality outcomes.

Complex Geometries with Angle Machine Vises

Angle machine vises provide solutions for machining parts with non-perpendicular features. They allow operators to position workpieces at specific angles.

Drilling Angled Holes

Drilling angled holes is a common task for angle machine vises. These vises adjust the clamped workpiece up to 90 degrees. This allows optimal positioning for drilling holes at precise angles without re-fixturing the part. This capability is particularly useful for custom fabrication and specialized component manufacturing.

Milling Bevels

Milling bevels also benefits from angle machine vises. A bevel is an angled surface or edge. Operators can tilt the workpiece to the desired angle using the vise. This setup allows the milling cutter to create accurate bevels on the workpiece's edges. This is useful for preparing parts for welding or for aesthetic finishes.

Efficient Production with Self-Centering Machine Vises

Self-centering machine vises significantly boost efficiency in production environments. They simplify workholding for various stock types and streamline repetitive tasks.

Centering Round or Square Stock

Self-centering vises automatically align workpieces. They ensure the part's center matches the machine's spindle. This feature is crucial for both round and square stock. Operators place the material between the jaws. The vise then clamps it precisely in the center. This eliminates manual adjustments. It also reduces setup time. This capability is especially beneficial for parts requiring concentric machining.

Repetitive Machining Tasks

Self-centering vises excel in repetitive machining tasks. They are perfect for mass production of identical components. These vises reduce inspection frequency, saving time on quality control. They also minimize operator error and training requirements. Operators do not need to manually reposition parts during changeovers. This simplifies clamping of workpieces with varying sizes. It also supports faster transitions between production runs.

Furthermore, these vises offer simplified programming. They eliminate the need for part-specific XY offsets. This simplifies CAM programming. It also reduces cycle variations. Machinists spend less time measuring and squaring parts. This allows for quicker loading, clamping, and running. Self-centering vises enhance part repeatability. They ensure every part is fixtured identically. This reduces cumulative errors over long production runs. They also lead to less operator dependency. This enables consistent and accurate part production with minimal training. Even new or night-shift operators can achieve high precision.

Automated Operations with Power Machine Vises

Power machine vises are essential for automated operations. They provide robust clamping force and integrate seamlessly into modern manufacturing setups.

High-Volume Production

Power vises are ideal for high-volume production. They use hydraulic or pneumatic systems for clamping. This provides consistent and powerful grip. Operators can quickly load and unload workpieces. This reduces cycle times. The automated clamping process minimizes physical effort. It also increases throughput. These vises ensure uniform clamping force across many parts. This consistency is vital for quality control in large batches.

CNC Machining Centers

CNC machining centers greatly benefit from power vises. These vises integrate with the machine's control system. This allows for automated clamping and unclamping. This capability is crucial for lights-out manufacturing. It also supports complex multi-axis machining. The precise and repeatable clamping of a power machine vise ensures workpiece stability. This stability is necessary for achieving tight tolerances. It also prevents part movement during high-speed cutting operations.

Key Advantages of Each Machine Vise Type

Different machine vises offer distinct benefits. These advantages help workshops achieve specific goals. Choosing the right vise improves efficiency and quality.

Benefits of Standard Machine Vises

Standard machine vises are fundamental tools. They provide reliable workholding for many tasks.

Versatility for General Machining

Standard machine vises offer great versatility. They handle a wide range of general machining operations. Operators use them for milling, drilling, and grinding. Their simple design makes them easy to set up. They adapt to various workpiece shapes and sizes. This makes them a go-to choice for everyday workshop needs.

Cost-Effectiveness

Standard machine vises are often more affordable. Their lower cost makes them accessible for many workshops. They provide excellent value for their functionality. This makes them a smart initial investment. Workshops can equip their machines without a large budget.

Advantages of Precision Machine Vises

Precision machine vises are crucial for demanding applications. They deliver superior accuracy and consistency.

High Accuracy for Fine Work

Precision machine vises ensure exceptional accuracy. They securely hold workpieces, allowing precise machining with minimal deviation. This leads to consistent quality and reduced scrap rates. For example, aerospace component manufacturers report a 15% reduction in rework. Medical device manufacturing sees improved feature accuracy and compliance with strict standards, boosting throughput by up to 20%. Electronics and semiconductor fabrication achieve a 10% increase in yield rates. They also produce fewer defective units by securely holding tiny components for micro-milling and assembly. These vises provide a stable platform, ensuring consistent results across multiple operations.

Repeatability for Batch Production

Precision machine vises offer excellent repeatability. They maintain consistent clamping force and position. This consistency is vital for batch production. Operators can produce many identical parts with high confidence. Quick and secure clamping also minimizes setup time, increasing overall productivity.

Strengths of Angle and Self-Centering Machine Vises

Angle and self-centering machine vises solve specific workholding challenges. They enhance flexibility and efficiency.

Complex Angle Machining Capabilities

Angle machine vises allow operators to position workpieces at precise angles. This capability is essential for complex geometries. They enable drilling angled holes and milling bevels. This eliminates the need for custom fixtures. It simplifies setup for non-perpendicular features.

Efficient Centering for Round Stock

Self-centering machine vises automatically align workpieces. They ensure the part's center matches the machine's spindle. This significantly boosts machining precision. It ensures consistent results for tasks like finishing, drilling, and milling. These vises allow for quicker workpiece clamping without extensive manual adjustments. This saves time and increases overall productivity. Available in 5-axis configurations, they offer greater flexibility for CNC applications. They also accommodate larger workpieces. Features like extra tall jaws provide improved spindle clearance. This is crucial for various machining operations. Adjustable centerlines further enhance precision and adaptability. Movable jaws ensure proper part securing without jaw lifting. This prevents issues during machining.

Power and Efficiency of Hydraulic and Pneumatic Machine Vises

Hydraulic and pneumatic machine vises offer significant advantages in modern workshops. They provide robust clamping force and enhance operational efficiency. These power-driven vises are essential for demanding tasks and automated production lines.

Increased Clamping Force

Hydraulic vises deliver powerful and precise clamping. They use fluid pressure to secure workpieces. This high clamping force suits demanding tasks and heavy-duty operations. It ensures workpieces remain stable during machining. This stability prevents slippage, enhancing accuracy and safety. Consistent pressure is crucial for industries requiring tight tolerances. Hydraulic vises provide this consistency. They offer precise and repeatable clamping, which is essential for maintaining high quality.

Reduced Operator Fatigue

Both hydraulic and pneumatic vises significantly reduce operator fatigue. Pneumatic vises excel in operator efficiency. They use compressed air for quick clamping and unclamping. This process significantly reduces setup times. Operators spend less effort manually tightening vises. This boosts productivity, especially in high-speed and repetitive machining tasks. Hydraulic vises also streamline workflows. They allow quick clamping and releasing with minimal effort. This reduces setup times and increases output, particularly in high-volume production. Their ability to integrate into automated systems further improves operational efficiency. This makes them a valuable machine vise for modern manufacturing.

Choosing the Right Machine Vise for Your Project

Selecting the correct machine vise is a critical step for any machining project. It directly impacts the precision and safety of operations. Identifying the correct type and size of vise for workholding is crucial for securing the workpiece during milling, ensuring precision machining. A well-chosen vise ensures the workpiece remains stable, preventing errors and potential hazards.

Critical Factors for Machine Vise Selection

Several factors guide the selection of a machine vise. These considerations help workshops choose the most suitable tool for their specific needs.

Workpiece Material and Size Considerations

The material and size of the workpiece significantly influence vise selection. Operators must consider jaw width, jaw opening, and throat depth. Jaw width determines the maximum workpiece width a vise can hold. Jaw opening indicates how wide the jaws can open, accommodating larger material sizes. Throat depth measures the distance from the jaw top to the base, affecting the accessible workpiece area. For example, harder materials like iron and steel often require hydraulic vises for heavy-duty machining. Softer materials such as copper, aluminum, or plastic benefit from mechanical vises, which prevent lifting and bowing. Mini vises, despite their small size, offer excellent clamping force. They are ideal for machining short series or workpieces with frequent shape changes, providing versatility and efficiency. Additionally, operators must assess the material size to ensure the clamp is long enough for necessary pressure. The material shape, whether irregular or round, may necessitate specialized clamps. Project size also matters; small pieces are easily held, while larger projects require more support, possibly needing heavy-duty clamps or multiple smaller ones.

Required Clamping Force Assessment

Assessing the required clamping force is essential. Different materials and operations demand varying levels of pressure. Hardwood, for instance, needs more force than softwood. The vise must provide sufficient force to hold the workpiece securely without deforming it. This prevents movement during machining, which maintains accuracy and safety.

Desired Precision Level Determination

The desired precision level directly influences the type of vise needed. High-precision tasks, such as grinding or EDM, require vises with exceptional accuracy and minimal deflection. Standard vises suit general machining where tolerances are less stringent. Precision vises, like toolmaker's vises, feature hardened and ground surfaces for superior parallelism and perpendicularity.

Type of Machining Operation Analysis

Analyzing the type of machining operation helps determine the best vise. Milling operations often use standard or CNC vises. Drilling might use a drill press vise. Grinding requires precision grinding vises. Complex angled cuts benefit from angle vises. Each operation has specific workholding requirements that a particular vise type fulfills best.

Matching the Machine Vise to Your Machine Tool

Properly matching the machine vise to the machine tool ensures optimal performance and safety. Compatibility considerations vary for different machines.

Milling Machine Compatibility

Milling machines often use robust vises. CNC vises, for example, feature a compact design and rigid holding. They are precision ground on multiple sides for sideways or horizontal clamping. These vises typically lack a flange, making them suitable for multiple vises on a machine due to their smaller stance. However, they require special table clamps for securing.

Grinding Machine Compatibility

Grinding machines demand high precision workholding. Toolmaker vises are smaller, inexpensive, and accurate. They often feature multi-step latch tightening and a lock-down design. These vises typically lack replaceable jaws or work stops. They are highly portable, making them ideal for moving work between machines like a drill press, mill, surface grinder, or a larger machinist vise without disturbing the workpiece.

Drill Press Compatibility

Drill presses have unique vise requirements. It is often suggested to have a separate vise for each machine. This avoids the repetitive and time-consuming process of unbolting, rebolting, and realigning a single vise between a mill and a drill press. Milling vises can be considered overkill for a drill press because the primary forces on a drill press are perpendicular to the table, unlike the sideways forces encountered in milling. The weight and size of a milling vise can also be a compatibility issue for some drill presses, potentially being too heavy or large for the drill press table. Some users successfully adapt a milling vise for drill press use, even if it is not ideal, sometimes by clamping smaller vises inside the larger one for specific tasks. Drill press vises often feature an open middle design. This allows drilling straight through, a feature typically absent in most milling vises. Without this feature, operators could drill into the vise itself if not careful.

Practical Tips for Working with Machine Vises

Proper use and maintenance of machine vises ensure precision and extend tool life. Operators benefit from understanding best practices for setup, clamping, and routine care.

Proper Machine Vise Setup Techniques

Correctly setting up a machine vise is fundamental for stable and accurate machining. This involves securing the vise and aligning its jaws.

Securing the Machine Vise to the Machine Table

Operators must securely fasten the machine vise to the machine table. This prevents movement during machining operations. For single or low-quantity production, a single vise setup with appropriate jaws works well. For higher quantity production, multiple vise setups maximize parts produced per cycle. High-precision vises reduce part deflection during heavy cutting. They use heat-treated and ground steel construction. This provides high clamping force with stable jaw contact. It minimizes workpiece bending or lifting. This prevents dimensional errors and poor surface finish.

Aligning the Machine Vise Jaws

Aligning the vise jaws ensures parallel clamping and accurate workpiece positioning. High-quality vises offer highly controlled parallelism and squareness. They provide uniform clamping pressure. This ensures secure seating for accurate referencing. This allows for tight tolerances across production batches. It also reduces measurement and rework time. Quick-change jaws and fixed datum positions contribute to quicker setups.

Effective Workpiece Clamping in a Machine Vise

Effective clamping prevents workpiece movement and damage. Operators use specific techniques to achieve this.

Preventing Workpiece Lift

Proper clamp selection and positioning keep the workpiece steady against locators. This prevents movement, especially when cutting tools exit the material. Clamps must be strong enough to prevent movement without counteracting main cutting forces. Operators position clamps to direct force into supports or locators. This prevents workpiece deformation.

Using Soft Jaws and Parallels

Operators use soft jaws and parallels to protect workpieces and enhance clamping. Soft jaws prevent damage to delicate or finished surfaces. Parallels elevate the workpiece. This allows tool clearance and ensures parallel clamping. They also help distribute clamping forces evenly. This prevents workpiece damage. Operators select clamps that will not damage the workpiece. They use rotating pads or softer materials to avoid bending or marking.

Routine Maintenance for Machine Vise Longevity

Regular maintenance extends the life of a machine vise. It also ensures consistent performance.

Cleaning and Lubrication Practices

Operators regularly clean the vise. This prevents debris buildup and ensures smooth operation. They use a soft brush or compressed air to remove chips, dust, and contaminants. They apply the manufacturer's recommended lubricant to lead screws and other moving parts. This avoids excessive application. Removing chips from the vise surface is a daily task.

Inspecting for Wear and Damage

Operators periodically inspect all components. This includes jaws, handle, and base. They look for signs of wear, damage, or misalignment. They replace jaws if cracks, chips, or uneven wear appear. This maintains consistent clamping pressure. They also inspect the lead screw and nut for wear or damage. They replace them if excessive backlash or uneven movement is present. This ensures precision clamping. Implementing a robust preventative maintenance program is crucial for maximizing machinery lifespan.

Advanced Machine Vise Considerations

Workshops often encounter tasks requiring specialized workholding solutions. These tasks range from extremely heavy-duty operations to delicate, intricate work. Advanced machine vises address these specific needs.

Heavy-Duty Machine Vises for Demanding Tasks

Heavy-duty machine vises provide the robust clamping force and stability necessary for aggressive machining. They handle large workpieces and significant cutting forces.

TriMax M Machinist Vises

TriMax M Machinist Vises exemplify heavy-duty design. They feature a patented AngLock® mechanism. This mechanism minimizes jaw deflection. It ensures consistent clamping pressure for accurate and repeatable results. A durable ductile iron body provides stability and rigidity. Hardened vise jaws offer superior gripping power, even during heavy-duty cutting. These vises also offer versatility and flexibility. They have a modular jaw design for quick changes. They accommodate various workpiece sizes and shapes. Options include standard, machinable, and dedicated jaw plates. Their user-friendly design includes quick-release nuts and ergonomic handles. This allows effortless, one-handed operation. It enhances efficiency and productivity. Robust materials and meticulous craftsmanship ensure durability and longevity. They withstand rigorous machining environments. This provides extended service life and reduced downtime.

Large Workholding Capacity

Heavy-duty vises offer large workholding capacity. They securely clamp substantial workpieces. This is crucial for manufacturing large components. Their robust construction prevents movement. This ensures precision during demanding operations.

Mini Machine Vises for Delicate Work

Mini machine vises are essential for tasks requiring extreme precision on small or fragile parts. They provide secure holding without causing damage.

Small Scale Precision

Mini vises or small vises are ideal for delicate work. They offer small-scale precision. Pneumatic self-centering air vises are indispensable for delicate or intricate work. They securely hold parts without unnecessary movement. This is vital for delicate materials or complex machining operations requiring absolute precision. The use of soft jaws further prevents damage or marring of delicate or complex parts. Precision machine vises are crucial for delicate or intricate work. They maintain consistent and accurate clamping force. They securely hold workpieces without distortion or damage. They also allow easy adjustment and repositioning. This is essential for both small, intricate parts and larger components where accuracy and stability are paramount.

Intricate Component Holding

Mini vises excel at intricate component holding. They offer flexibility in positioning. This allows rotation, tilting, and adjustment at multiple angles. This is useful for intricate tasks like detailed assembly or forming operations. They provide secure gripping for various materials. These include metal, wood, plastic, and delicate surfaces. They hold parts without slipping, even in unconventional positions. Applications include medical devices, aerospace components, military/defense equipment, commercial products, and electronic devices. They are also useful for metalworking, woodworking, maintenance, and crafts. Specialized jewelers' or polishing vises and ball vises are also offered for intricate tasks.

Selecting the appropriate machine vise is paramount for optimal workshop efficiency and project success. Workshops must carefully consider specific needs and applications when investing in a machine vise. Factors like construction materials, such as durable cast iron or forged steel, and suitable jaw types are crucial. Mounting options, including fixed or swivel bases, and overall capacity also guide selection. The right machine vise enhances precision, safety, and productivity for every task.

FAQ

What is the primary function of a machine vise?

A machine vise securely holds workpieces during machining operations. It prevents movement, ensuring precision and safety. This stability helps achieve accurate cuts and finishes.

How do fixed base and swivel base machine vises differ?

Fixed base vises offer maximum rigidity. They bolt directly to the machine table. Swivel base vises provide flexibility. They allow operators to rotate the workpiece for angled cuts without unclamping.

When does a workshop use a precision grinding machine vise?

Workshops use precision grinding machine vises for high-accuracy tasks. These vises hold parts with extreme precision for grinding operations. They ensure tight tolerances and fine finishes.

What are the main advantages of a self-centering machine vise?

Self-centering vises automatically align workpieces with the machine's spindle. This boosts efficiency for repetitive tasks. They simplify clamping for various stock types, reducing setup time and operator error.

Why do some workshops choose hydraulic or pneumatic machine vises?

Hydraulic and pneumatic vises provide high clamping forces. They reduce manual effort and operator fatigue. These power vises are ideal for high-volume production and automated operations, increasing efficiency.

How does one choose the correct machine vise for a project?

One considers workpiece material and size, required clamping force, and desired precision. Analyzing the type of machining operation also guides the selection. Matching the vise to the machine tool is also important.

Why is routine maintenance important for machine vises?

Routine maintenance extends the vise's lifespan. It ensures consistent performance and accuracy. Regular cleaning, lubrication, and inspection for wear prevent debris buildup and maintain clamping precision.

RELATED NEWS

- EN-intallation video for Vortex Vacuum Pump 2024-05-31

CATEGORIES

CONTACT US

Contact: DY sales team

Phone: 0086 13586840757

E-mail: info@cnc-sparestore.com

Add: Room 2312, Zhenhe building, 225 north huanchengxi road, Haishu District, Ningbo City, Zhejiang Province, CHINA